ECOSTAN® How To Make Briquettes From Daily Wastes

Remember the old proverb, “One person’s trash is another person’s treasure”? For our everyday wastes, the very same logic stands true.

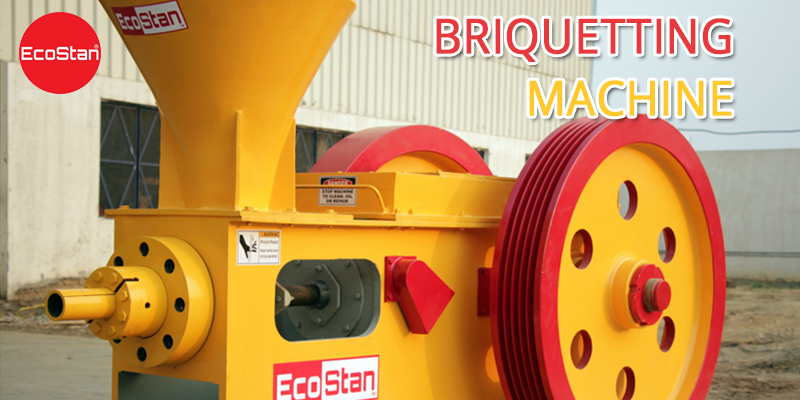

Following this theory, it is ideal for us to create briquettes using everyday waste with the help of the Briquetting Machine, a wonderful and almost inexhaustible energy source.

Briquettes are compact cubes of flammable material that you can use to ignite a fire. The popular ingredients that briquette machine uses to make briquettes are sawdust, moss, newspaper, woody biomass, and coal dust.

At present, hardwood and coal are the primary heat source and cooking fuels for nearly 50% of the earth’s population. The drastic cutting of forests for subsistence agriculture, food preparation, or domestic heating is not a smart option when you have a briquettes like decent choices available. That is the whole point of innovation: to make the world a safer place and to enhance human well-being.

Currently, the process of making briquettes by using everyday waste is growing to be widespread. Briquettes machine uses agricultural residues to make briquettes that you can use as “green” substitutes for hydrocarbons (coal, oil, etc.) for a wide range of commercial purposes, covering things like heating boilers and other things.

How can one extract the valuable “garbage” from everyday waste and turn it into briquette?

It begins with figuring out the content of the trash. In general terms, it is critical to evaluate the waste’s chemical components, caloric content, and moisture levels to make a briquette out of it.

- Moisture content: The collection of the wastes is directly affected by moisture levels. Various humidity meters are readily available to assess the moisture levels of trash. So, make sure you consider the moisture content, before finalizing the waste.

- Calorific value: The caloric worth of trash is based on its calorific value. Humidity and hydrogen concentration both influence the waste’s calorific value.

- Chemical composition: Chemical constituents of waste comprise components like carbon, oxygen, hydrogen, sulphur, nitrogen, and many others. The treatment of the waste is dependent on the chemical constitution.

Daily wastes for the manufacturing of briquettes:

Briquetting is a mindful technique for turning the waste materials into precious resources. By applying pressure and bonding chemicals, you can use the briquetting technique to compact scattered flammable components into various forms and sizes of hard composites.

In general terms, you can prepare briquette from various resources, including scratch paper, cardboard, agricultural residues, charcoal ash, hardwood debris like sawdust, and many others.

The process of making briquettes from everyday waste:

- Raw materials preparation: Raw materials are mechanically fragmented by crushing machines depending on the quality and size of waste material.

- Whenever the water content seems excessive for manufacturing briquettes, it becomes necessary to dry the crushed materials you get from everyday waste.

- You can utilise numerous briquetting machines, such as briquetting pressing machines, to process the material and turn it into briquettes that you may later use as fuel. The pressure aggregation is used to form stable, geometric, and specified measurements, compress free components under stress, resulting in the necessary inter molecular interactions and bindings.

Advantages of turning your everyday waste into briquettes:

- Recently, all are exploring ways to make their residences more eco-friendly and environmentally responsible. Now that everybody is aware of the issues that are coming with global warming, we are all researching how to alter our habits to prevent this problem and preserve the safety of our planet. Making briquettes from everyday waste utilizing a briquette making machine is the right response to this. Fossil fuel is the principal source of energy for the majority of the planet’s population, and coal is typically used to feed boilers that generate power for energy.

- Waste-derived briquettes are an excellent coal alternative since they use all the leftover materials, which helps you save tons of money and is environmentally friendly. Businesses are now opting for briquettes as an energy-producing source instead of coal. They are now working with briquette machines as these briquette machines use everyday waste and transform it into briquettes. Though they ignite similarly to charcoal, they have little or no negative environmental consequences. Both water heating and electricity production using turbines are possible with these briquettes.

- Briquettes generated from regular waste minimise the necessity to purchase and transport fossil fuels since they can be produced locally from animal and plant waste. Several nations without oil or coal sources will see their power bills decrease as a result. Everybody can benefit from affordable, secure energy.

- Due to the briquettes’ manufacturing, many companies now employ briquettes because these companies are now familiar with the advantages of briquettes and how they can reduce their carbon emissions and be available at a reasonable price. Long-term potential savings from using these briquettes over coal is tremendous. As a result of its environmental degradation, coal is currently one of the riskiest methods of energy production. This demands us to minimise our use of charcoal and find alternative energy sources. Given their accessibility and ease of use, making briquettes utilising everyday waste is an excellent way to accomplish this.

Conclusion:

We at Ecostan, are contributing to the global environmental cause, and encourage others to do the same, and make earth greener and livable. . And briquettes are more in demand as fuel because of the rising prices of conventional energy sources. The common uses of briquettes includes boiler plants, thermal plants, power generation, thermal power plants, and by individual customers for domestic consumption. If you also want a briquetting machine, you can purchase one from Ecostan.

Click to Play Video

Click to Play Video